What is a Beam Tack Welding Machine?

A beam tack welding machine is used to tack-weld two H-beams simultaneously using two welding torches positioned on either side. After steel plates are cut by CNC plasma or oxy-gas cutting machines, they are automatically assembled into H-beams by the tack welding machine through a hydraulic system and welding power source.

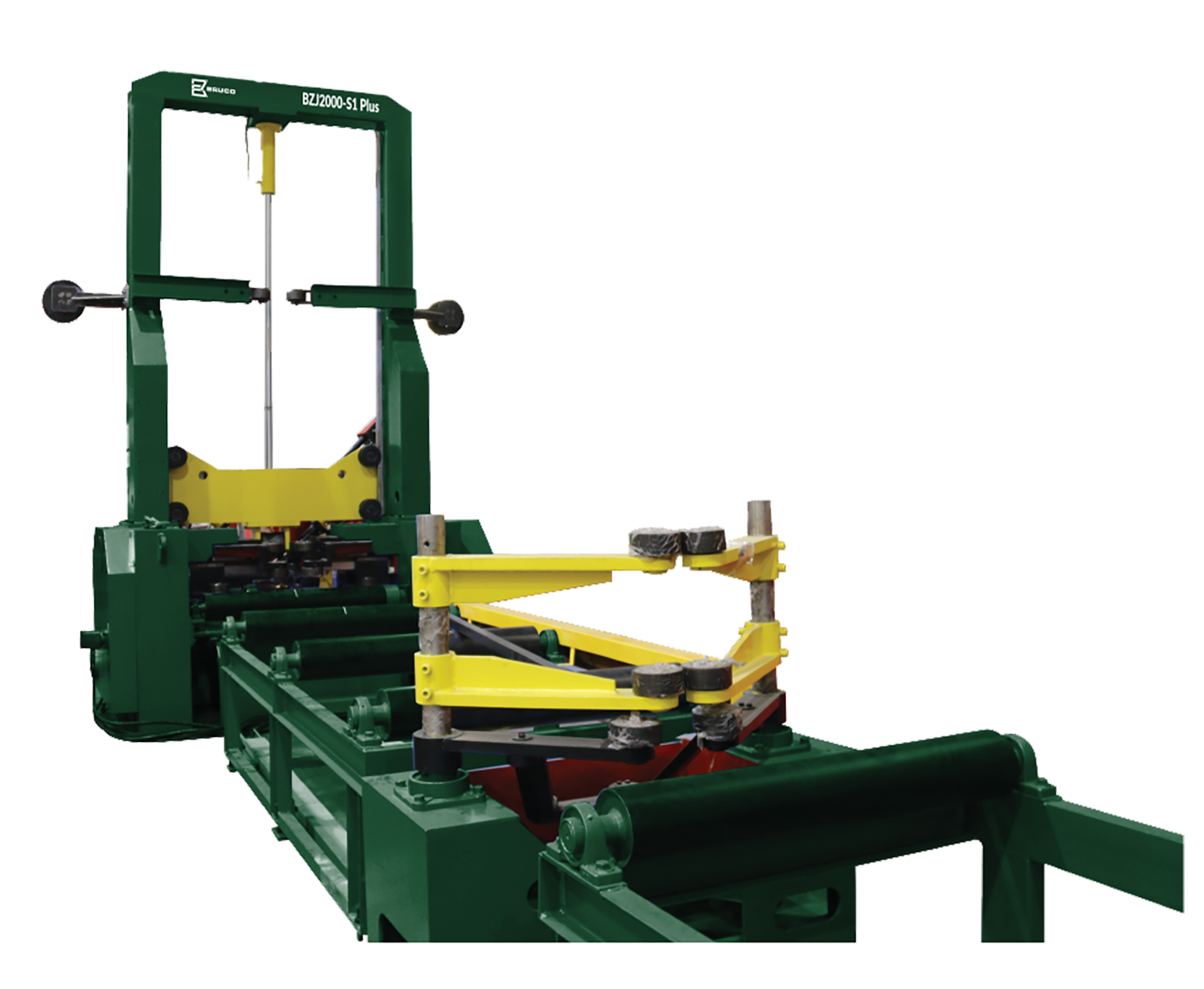

Why Choose the BZJ2000-S1 PLUS Intelligent H-Beam Tack Welding Machine?

The BZJ2000-S1 PLUS is a new-generation tack welding machine developed and improved by Bruco – Weldcom, based on comprehensive evaluations of previous models. This latest version features enhancements in both mechanical design and control technology to increase productivity and improve weld quality.

Key Advantages

-

Compact machine body with rigid structure, logical layout, and flexible design. The main drive motor is neatly integrated inside the machine frame.

-

The flange/web clamping system utilizes ball screws and hydraulic cylinders, offering firm clamping, wide working range, high stability, and precision.

-

Integrated flange support cylinders help support beams with flanges longer than the web or deformed flanges, minimizing manual handling.

-

User-friendly touch interface by KEYENCE with built-in SCADA and MES connectivity – no additional hardware required.

-

High tack welding speed, ranging from 0.6 to 3 m/min.

Machine Configuration of BZJ2000-S1 PLUS

Main Components:

-

Main machine body: upper beam, clamping system for web, flange and center, primary transmission & reducer, manual supports.

-

Output roller table

-

Input roller table

-

Hydraulic system: 1 set (oil pump station, high-pressure hoses, hydraulic cylinders)

-

Electrical control system: 1 set (control cabinet, cables)

-

Automatic welding system: 2 Weldcom VMAG 500 or Megmeet Artsen CM350R power sources

Centering Clamp System:

-

Beam flanges are centered by 4 pressing rollers; webs are centered by 8 rollers to ensure almost absolute accuracy (deviation < 1mm).

-

Easy removal of 4 web clamping rollers allows for tack welding of small-size beams (as small as 160 mm web height).

-

Smart, compact design allows for quick and accurate centering adjustments, even for off-center beams.

-

Clamping movement is driven by a hydraulic motor with chain transmission, using ball screws and linear guides for smooth and precise operation with low noise.

-

Additional auxiliary clamps ensure safe and accurate processing of large beams.

Pressing System:

-

Large, robust guide rollers for hydraulic pressing cylinders ensure stable pressure and easy adjustments.

-

Centerline alignment of pressing rollers guarantees clamping accuracy.

Welding Torch Assembly:

-

Welding torches are positioned precisely between the pressing cylinder and main drive roller, ensuring accurate tack welds with no gaps between web and flange.

-

The welding torch holder is firm and self-aligning, ensuring exact weld placement at the web-flange joint.

Drive System:

-

The main drive motor is enclosed under the machine bed, saving workshop space and improving safety.

-

Equipped with a 5.5 kW motor, the system supports loads up to 20 tons via reinforced rollers.

-

Roller conveyors are solidly welded and built with thick, high-strength tubing for long-term durability.

Electrical Control System:

-

Uses Yaskawa inverter for a compact control cabinet.

-

Compact yet fully functional control panel with intuitive operation.

-

PLC-controlled, enabling automatic centering, flexible weld length adjustment, and variable tack intervals.

Hydraulic System:

-

160L oil tank designed to be compact and space-saving for efficient workshop layout.

Technical Specifications – BZJ2000-S1 PLUS Intelligent H-Beam Tack Welding Machine

| No. | Description | Unit | Specification |

|---|---|---|---|

| 1 | Web height | mm | 160 – 2,000 |

| 2 | Web thickness (as per process) | mm | 6 – 80 |

| 3 | Flange width | mm | 150 – 800 |

| 4 | Flange thickness (as per welding process) | mm | 6 – 80 |

| 5 | Beam length (based on standard rail) | m | 4 – 15 |

| 6 | Welding position | 2F | |

| 7 | Tack welding speed | mm/min | 600 – 3,000 |

| 8 | Idle travel speed | mm/min | 200 – 4,500 |

| 9 | Machine power (excluding welding source) | kW | 9.5 |

| 10 | Power supply | AC380V / 3 Phase / 4 Wire / 50Hz |

Correlation Between Web Height and Flange Width

| Web Height (mm) | 160 – 295 | 295 – 390 | 390 – 530 | 530 – 2,000 |

|---|---|---|---|---|

| Flange Width (mm) | 150 – 275 | 150 – 460 | 150 – 650 | 150 – 800 |

Reviews

There are no reviews yet.